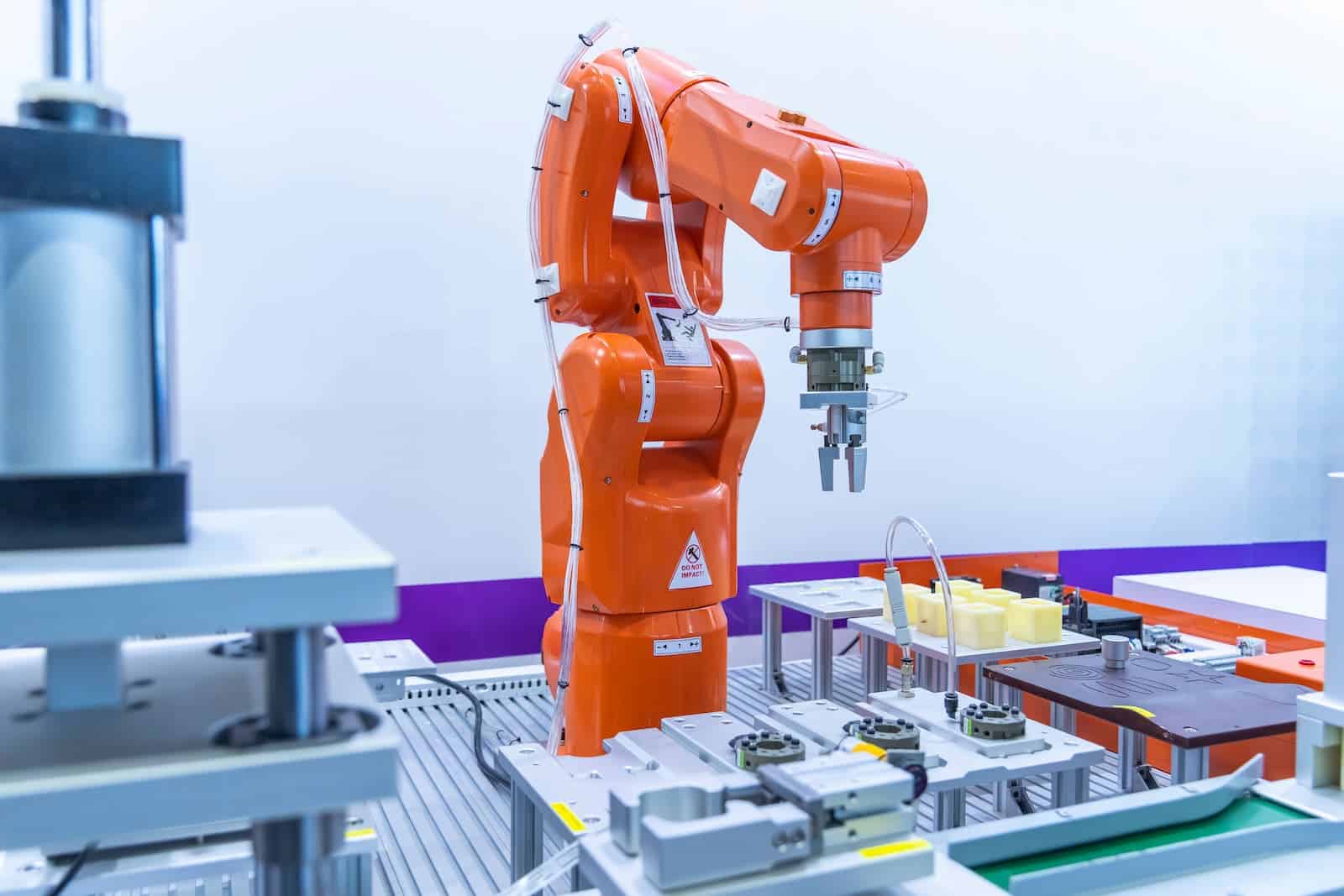

At the heart of our expertise in Industrial Robotics

B2C Engineering focuses on the integration of innovative and sustainable solutions, taking into account the needs and constraints, particularly financial, of our industrial customers.

B2C Engineering works on the design, integration, commissioning and maintenance of robotic islands with multi-brand robots, including the manufacture of customised and small series machines. We also offer robot integration simulation using Visual Components software in order to provide you with the optimum solution for your needs.

Coupled with a mastery of the latest market technologies from ABB, FANUC or Stöbl, our expertise also includes retrofitting and revamping of your automation systems. This way, your company will be able to improve its performance in a sustainable development and investment process.

Zoom on a robotisation mission for one of our customers in the transport sector.

The technical project

Description of the project

B2C Engineering was entrusted with a mission of robotization in the casting of prefabricated concrete elements, for one of our customers in Belgium.

Our team studied the operation of the installation on the basis of the functional analysis provided by the client in order to set up a programming adapted to the process.

Together with our electrical partner, we took care of the electrification of the entire system.

The team then worked on the automation part and carried out the developments in accordance with the customer’s standards.

Scope of supply

SIEMENS S7-1512SP-Failsafe PLC programming

Hardware configuration CPU and I/O boards

Parameterisation of SEW Movi-C frequency inverters

Exchange tables to the robot, the customer PLC (interaction with the production line), the vision system

Development of the sequence program according to the functional analysis provided by the customer

Management of the 2-axis robot of the automatic parts shop

HMI programming SIEMENS KTP1200 Basic

Overview of the machine

Status of the safety devices

Parameter views (frequency inverters, PI positioning control, robot speed, offsets, etc.)

Alarms view

Manual control view

Operator view magazine loading/unloading

Robotic programming FANUC M-10iD/16S-30P-A

Axis settings, robot frames + configuration

Programming of general operation Grafcet

Programming of corrections by Vision feedback

7th axis and DCS programming

Teach and optimization of trajectories

Keyence LJ-X8000E + LJ-X8400 profilometer setup

Profile recognition tools setup

Detection of the required profile

Sending positioning corrections to the robot

Finally, B2C took care of the coordination of the commissioning, including a test phase to verify the correct operation and optimisation of the system.

Gains for clients

Our customer benefits from a new robot that :

- Optimises the production of concrete sleepers

- Saves time, achieving a 99.5% success rate in the removal of handled parts

Discover our other partners and find all our expertise on our page dedicated to Robotics.